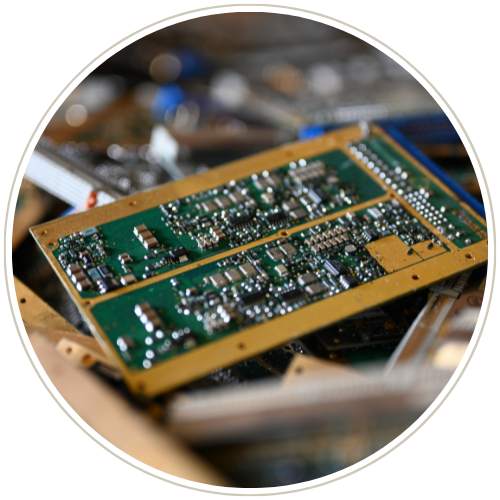

As an E-Scrap collector, you know when it comes to electronic scrap refining you could have a gold mine (or silver, or palladium!) in your possession. Many devices like phones, computers, cameras, and key fobs contain small amounts of precious metals, which can be recovered.

Shred sampling is the norm for processing specific grades of e-scrap lots and, in most cases, is the process that makes

the most economic sense. Especially concerning material like consumer electronics, power supplies, circuit boards, and cable television circuit boards. Generally, the process involves placing e-scrap on a conveyor belt, shredding it with massive blades, then passing it through a screen, after which random samples are taken.

Certainly, this process is a better way to take a sample than just taking a scoop of material and testing it. Still, when processing electronics by only shredding and screening, valuable components can fall through the cracks. What if

tiny scraps of gold are what is falling through those cracks?

Shred sampling will not capture it, making it highly likely your return will be lower.

At Gannon & Scott, 100% of your e-scrap is processed, metallics/plastic e-scrap is thermally reduced. Metallic only

scrap is melted. In the case of thermal reduction, a homogenous mix of a very fine powder is created, and the

powder is mixed, sampled, and analyzed. When melting any oversize, a sample is taken while the metal is still

molten.

This extra effort offers a far more accurate analysis, which means your returns are based on science, not chance. Plus,

with our Certified Destruction service, you’re guaranteed that intellectual property or data within your e-waste cannot be

recovered in any way once processed at our facility.

Shred sampling lacks the security of total destruction.

Simply shredding and screening isn’t a guarantee that the sensitive information will not end up in the wrong hands when it leaves the facility. Everything received at G&S is destroyed by the method to make materials homogenous in order to be sampled. Nothing is harvested or resold.

Gannon & Scott is also only one of a handful of companies recognized by the NSA, DoD, and DSCA to certify-destroy

equipment and devices that handled highly classified materials. According to the NSA and DoD, thermal processing in

conjunction with size-reduction is the most efficient form of certified destruction for electronics and memory.

What about environmental concerns regarding thermally reducing e-waste?

We’ve already thought of that. Our process specifically cleans the emissions created during processing to prevent

releases from the furnaces, which dramatically reduces the number of toxins going into the air and meets all applicable

regulations.

When we’re the ones handling your e-scrap, you can rest assured that you’ll get the most precious metal recovery value possible

in the industry.