Thermal Reduction, Milling, and Blending

Gannon & Scott offers a highly versatile range of thermal reduction capabilities to meet our customers' diverse needs.

Our thermal reduction facilities are among the most advanced and environmentally sound in the industry.

We uphold a commitment to quality by maintaining batch integrity throughout the thermal reduction, milling, and sampling process to ensure you get the highest return from each refining lot.

This video describes the First Step in the Thermal Reduction Process.

Gannon & Scott's combined thermal reduction capabilities allow us to meet virtually any need or specification you may have.

We can handle a wide variety of material forms and process small batches of material to full truckload volumes.

Our combined thermal reduction rate is over 1200 pounds per hour.

Our milling and blending equipment can handle a wide range of jobs from 5 to 4000 pounds, depending on our client’s needs and the types of materials to be processed.

Types of material processed:

- Polishings

- Filters

- Wipes/rags

- Circuit Boards

- Flexi-Circuits

- Electronic Scrap

- Connectors

- Carbon-Based Materials

- Resins

- Sludges

- Floor Sweeps

- Pastes

- Material destruction

- Industrial catalysts

- Slags

- Crucibles

- Industrial Ceramics

Our versatility makes us the go to choice among metal refining and recovery companies in the USA and across the globe.

Watch a video timelapse of our TR as It burns 10 gaylords of debris material in hours.

Saving our customer several weeks of process time.

New Milling Technology

Take a sneak peek at our new mills.

We have some very interesting reclaim data on them that we'd love to share.

Contact us and we can show you how these new mills can help you recover more, and worry less!

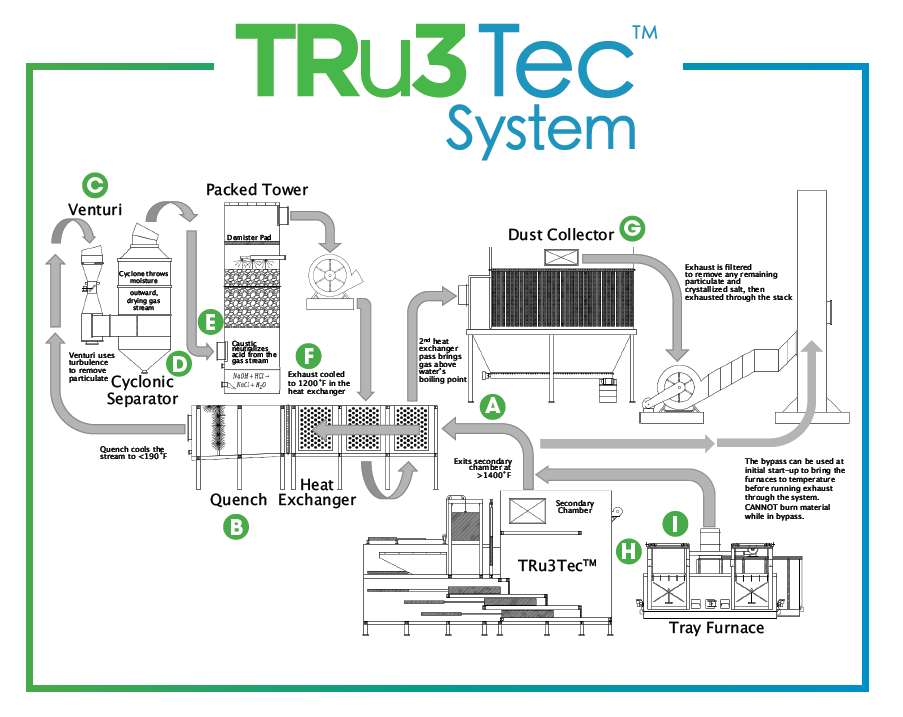

Pollution Control White Paper

Meeting the Challenge of Sustainable Precious Metal Recovery

This white paper discusses how Gannon & Scott is advancing PM recovery with a thermal reduction system that uses a state-of-the-art pollution control process.