Reclaiming precious metals through refining is a great way to put money back in your business… and sloppy shipping is a great way to reduce your returns. To help ensure your refining lots arrive in one safe and valuable piece, we’ve compiled a list of the top six mistakes that can sabotage your shipments and hurt your revenue.

1. Overloading your containers

We’ve seen some badly overstuffed boxes get to our dock and collapse as soon they’re unloaded. If that happens at our facility, our staff will sweep up as much of the debris as

possible to recover every ounce of your precious metal. But if it happens at another stage in transit, you could lose a fair amount of value.

Remember that freight gets handled many times as shipping trucks pass through terminals, loading and unloading cargo. If your box bursts somewhere in transit, there’s no guarantee the carrier will try to pick up every little bit of lost material.

2. Using wimpy packaging

Here’s a common theme: a customer fills a cardboard box with small parts, the box gets nicked by a forklift in transit, and parts are spilling out the bottom by the time the box arrives at our facility. This can be avoided by using metal drums or wooden crates—just don’t forget to inspect them for weak spots.

If you’re going with cardboard boxes, know that not all gaylord boxes are created equal. Forks can easily penetrate single- or double-walled boxes, so if you’re using cardboard,

make sure it’s triple-walled.

3. Stacking non-stackable pallets

Some people opt to stack pallets to save on shipping costs, since they’re using one pallet space instead of two. But if your shipment includes heavy materials and your pallets aren’t specifically designed to be stacked, you risk breaking the lower pallet and damaging your

freight.

If you’re trying to save space, do everything you can to keep your pallet compact. Try stacking an extra row of boxes on top of a pallet, or pack your boxes more densely to

eliminate empty spaces.

4. Shipping everything in your dumpster

As best you can, try to keep plain old garbage out of your refining lots—you should be shipping only recoverable materials. It’s better if a refiner can get to work without having

to first remove extraneous junk, especially if you’re getting charged by the pound for processing. Some refiners will charge higher fees and give you less metal accountability if

your lots are too diluted.

5. Playing the “mystery sender” game

This sounds like a no-brainer, but we’ve received shipments with no identifying

information. Make sure you put a name and phone number on the outside of every box. This

could be your company name or, if you’re concerned about security, the name of an individual. That way, if a box gets orphaned, someone can reach you.

If you’re shipping five boxes, each one needs a reference number and contact info.

Also, if you’re reusing gaylord boxes from another company, please remember to change the identifying info from their info to yours! Yeah, we’ve seen that mistake too.

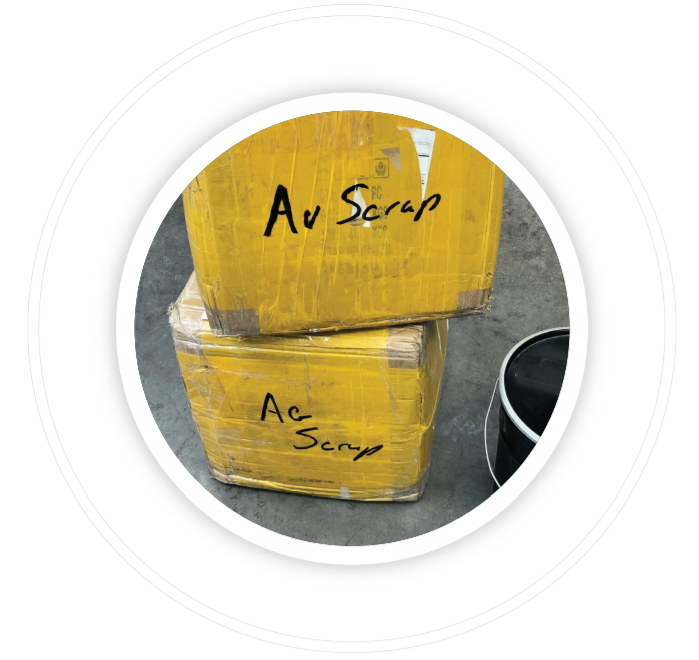

6. Revealing the contents

Even if you’re shipping low-value material, you never want anybody to see what’s inside your shipment. If you’re sending a gaylord box full of scrap, cover the top with cardboard

and stretch-wrap the entire box to hide the contents. Consider using black stretch wrap for another layer of security.

Also, never write anything on the box that indicates high-value contents. We’ve seen people write “gold scrap” directly on their shipments, which is a great way to let thieves know what’s inside. Even worse, we’ve seen shipments come in open containers with clear plastic wrap, clearly showing the precious metal cargo. Might as well put a neon “Steal Me!” sign on there, too.

Don’t rely on a thief not understanding periodic table abbreviations. A quick Google search for “Au” and your lot could be gone before it leaves the shipping dock.